Micromanufacturing: Revolutionizing Production at the Microscale

Micromanufacturing is reshaping industrial practices, enabling the production of intricate components at a scale previously thought impossible. This cutting-edge approach to manufacturing is opening new frontiers in various sectors, from medical devices to aerospace technologies. As industries seek to miniaturize products while enhancing functionality, micromanufacturing emerges as a game-changing solution, promising unprecedented precision and efficiency in production processes.

Historical Context and Technological Evolution

The roots of micromanufacturing can be traced back to the semiconductor industry in the 1960s, where the need for miniaturization drove innovations in microfabrication techniques. Initially limited to electronics, these technologies gradually found applications in other fields. The advent of advanced materials, precision control systems, and sophisticated modeling tools in the 1990s and 2000s accelerated the development of micromanufacturing capabilities.

Today, micromanufacturing encompasses a diverse range of techniques, including micro-electrical discharge machining (micro-EDM), focused ion beam (FIB) technology, and two-photon polymerization. These methods allow for the creation of complex 3D microstructures with unprecedented precision, opening up new possibilities in product design and functionality.

Applications Across Industries

The versatility of micromanufacturing has led to its adoption in numerous sectors. In the medical field, it enables the production of minimally invasive surgical tools, micro-fluidic devices for diagnostics, and drug delivery systems. The aerospace industry utilizes micromanufacturing for creating lightweight, high-strength components and sensors for aircraft and satellites.

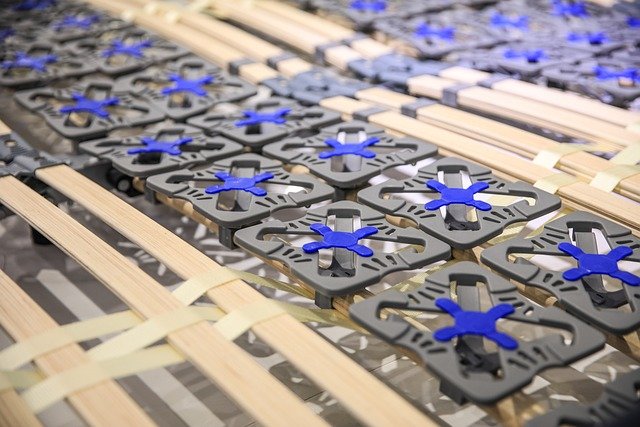

In electronics, micromanufacturing is pivotal in producing microprocessors, MEMS (Micro-Electro-Mechanical Systems) devices, and miniaturized sensors. The automotive sector benefits from micromanufactured components in engine management systems, safety sensors, and fuel injection systems. Even traditional industries like textiles are exploring micromanufacturing for creating smart fabrics with embedded microsensors.

Economic Impact and Market Trends

The global micromanufacturing market is experiencing rapid growth, driven by increasing demand for miniaturized products across various sectors. According to industry reports, the market is expected to reach $6.5 billion by 2025, with a compound annual growth rate (CAGR) of 14.3% from 2020 to 2025. This growth is fueled by advancements in materials science, increasing investment in R&D, and the expanding applications of micromanufactured products.

The economic impact extends beyond direct market value. Micromanufacturing is enabling the development of more efficient, compact, and high-performance products, leading to cost savings in materials, energy consumption, and transportation. It’s also fostering innovation in various fields, potentially creating new market segments and job opportunities in high-tech manufacturing.

Challenges and Future Directions

Despite its potential, micromanufacturing faces several challenges. The high initial investment in equipment and technology can be a barrier for smaller companies. There’s also a need for specialized skills and knowledge, which requires investment in workforce training and education. Quality control and consistency at the microscale present unique challenges, necessitating advanced inspection and testing methods.

Looking ahead, the future of micromanufacturing is promising. Ongoing research in nanotechnology and materials science is pushing the boundaries of what’s possible at the microscale. The integration of artificial intelligence and machine learning in micromanufacturing processes is expected to enhance precision, efficiency, and automation. Additionally, the convergence of micromanufacturing with other emerging technologies like 3D printing and bioprinting could lead to groundbreaking applications in tissue engineering and personalized medicine.

Practical Insights for Businesses Exploring Micromanufacturing

• Conduct a thorough cost-benefit analysis before investing in micromanufacturing technology

• Collaborate with research institutions or specialized firms to access expertise and resources

• Start with pilot projects to assess the feasibility and potential of micromanufacturing for your specific needs

• Invest in employee training and development to build in-house expertise

• Stay informed about regulatory requirements, especially for medical and aerospace applications

• Consider the entire product lifecycle, including maintenance and recyclability of micromanufactured components

Micromanufacturing represents a paradigm shift in production capabilities, offering unprecedented precision and efficiency at the microscale. As industries continue to demand smaller, more complex components, the role of micromanufacturing in shaping future products and technologies becomes increasingly significant. By understanding its potential, challenges, and future directions, businesses can position themselves to leverage this transformative technology, driving innovation and competitiveness in the evolving industrial landscape.